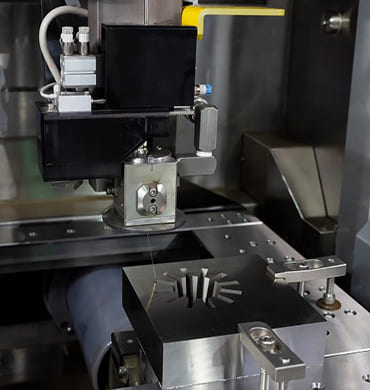

Electrical Discharge Machining (EDM)

The PMI Group offers its clients the following advantages and benefits of EDM machining processes:

- Achieving difficult geometries such as long narrow slots, sharp corners, and splines

- Racking and stacking of parts to achieve economies of scale

- The ability to cut any conductive material including exotic alloys such as titanium, inconel, tungsten, cobalt, hastelloy, etc.

- Reduced tool wear as the wire is continually replenished

- Hardness of parts does not affect cycle time

- Very accurate tolerances can be held up to .0001”

- Burr free finishes